Preventative maintenance is a crucial step in keeping your HVAC system running efficiently and safely. By addressing potential issues before they turn into total malfunctions, routine maintenance helps ensure optimal performance and extends the lifespan of your equipment. Whether it’s checking the thermostat, inspecting filters, or tightening electrical connections, these checks are designed to keep your system in peak condition year-round.

An HVAC Preventative Maintenance Check is about checking every component for any abnormalities, as there are often signs of trouble weeks or months before it becomes apparent.

Checking Airflow

It’s important for technicians to make sure airflow is as uninterrupted as possible. When airflow is bad, it can cause system strain, leading to higher energy costs. With exceptionally bad airflow, you can get freezing of the evaporator coils, leading to a system breakdown.

AC Air Filter Check

The air filter is removed and thoroughly inspected for dust, debris, and clogs. If it is dirty or obstructed, it is either replaced or cleaned, depending on the type of filter. Ensuring the filter is clear maintains proper airflow through the system and supports optimal operation.

Clean filters are essential for maintaining unobstructed airflow, as they prevents the system from overworking to push air through clogged passages. This reduces energy consumption, lowers the risk of system failures, and ensures the air circulating in the home is free of dust, allergens, and other airborne contaminants. An exceptionally dirty filter can cause coils to freeze, leading to system malfunction.

Ductwork Examination

Technicians inspect the ductwork for visible damage, blockages, or leaks. This includes checking for debris buildup, loose connections, and collapsed sections. Repairs or cleaning are performed as necessary to eliminate restrictions and ensure the air can move freely throughout the HVAC system.

Efficient ductwork is critical for air distribution. Blockages or leaks reduce system efficiency, increase energy consumption, and cause uneven cooling or heating. Addressing these issues ensures better airflow, maintains comfort levels in all areas, and prevents unnecessary strain on the HVAC system.

Motor Performance Assessment

The motors within the system are tested to measure amperage, ensuring they operate within the manufacturer’s recommended range. This involves using specialized tools to assess motor efficiency and identifying signs of excessive heat, low performance, or other operational concerns.

Motor performance directly impacts the airflow in the system. An overworked or inefficient motor can reduce airflow, leading to uneven cooling and higher energy bills. Monitoring amperage also helps identify potential issues early, reducing the risk of costly breakdowns and prolonging the motor’s life.

Bearing Inspection

The bearings in the motor are inspected for signs of wear or damage, such as rough spots or looseness. Lubrication is applied if necessary to ensure smooth operation. Worn bearings are replaced to prevent additional strain on the system.

Damaged or poorly lubricated bearings can cause increased friction, leading to motor inefficiency, noise, and potential failure. Proper maintenance of bearings helps the motor function efficiently, ensuring steady airflow and preventing unnecessary strain on the system’s components.

Outdoor & Indoor Coil Cleaning

Both the indoor evaporator coil and outdoor condenser coil are inspected and thoroughly cleaned. Technicians remove dirt, dust, and debris using specialized cleaning agents, brushes, and water. Indoor coils, often located in hard-to-reach areas, are carefully cleaned to prevent damage. Outdoor coils are cleared of leaves, dirt, and other obstructions that accumulate over time. This process also includes checking the coil fins for bending or damage and straightening them if necessary to promote optimal airflow.

Clean coils are critical for maintaining efficient heat exchange in the system. The indoor evaporator coil absorbs heat from the air, while the outdoor condenser coil releases it. When coils are dirty, they can’t transfer heat effectively, leading to higher energy consumption, reduced cooling capacity, and increased wear on the system. Cleaning also prevents mold and bacteria buildup on indoor coils, which improves air quality and prevents unpleasant odors. Regular coil maintenance reduces system strain, prolongs equipment lifespan, and ensures consistent and reliable airflow throughout the home or building.

Checking Electrical Components

Thermostat Inspection

The thermostat is inspected to ensure it is calibrated correctly and functioning properly. Batteries are checked and replaced if necessary. Programmable thermostats are verified for accurate scheduling and settings to maintain desired indoor temperatures.

A properly functioning thermostat ensures the HVAC system operates efficiently by preventing unnecessary cycling and maintaining consistent temperatures. Accurate calibration reduces energy waste, ensures comfort, and avoids strain on the system caused by inaccurate or erratic operation.

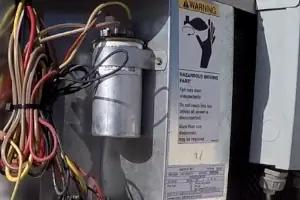

Capacitor Testing

Capacitors are tested using a multimeter to verify their ability to hold and release electrical charges. Weak, leaking, or failing capacitors are replaced to prevent motor startup or operational issues that could disrupt the system’s function.

Capacitors are critical for starting and running HVAC motors. Faulty capacitors can cause motors to overheat, fail, or struggle to start. Replacing worn capacitors helps maintain consistent airflow, improves energy efficiency, and prevents costly motor or compressor damage.

Electrical Connections

All electrical connections, wires, and terminals are inspected for signs of wear, corrosion, or looseness. Loose connections are tightened, and damaged wiring is repaired or replaced to ensure proper electrical flow throughout the system.

Secure and intact electrical connections prevent short circuits, voltage drops, or system failures. Proper wiring ensures safe operation, reduces fire risks, and keeps components like motors and capacitors functioning reliably, contributing to the system’s overall performance and longevity.

Checking Coolant

Coolant levels are measured using pressure gauges and a manifold set to ensure they meet the manufacturer’s specifications. Technicians assess the system’s pressure and temperature readings to confirm proper refrigerant charge. If levels are low, we inspect for leaks using electronic leak detectors or UV dye. After repairs, refrigerant is recharged to the appropriate level for optimal system performance.

Furnace Checks for Winter

Furnace checks involve inspecting the heat exchanger for cracks, testing gas pressure, and ensuring burners are clean and operational. Technicians also verify ignition systems and airflow. These checks are essential to maintain efficiency, prevent carbon monoxide leaks, and ensure reliable heating. Regular maintenance extends the furnace’s lifespan and minimizes the risk of costly breakdowns during colder months.

Benefits of A HVAC Preventative Maintenance Check

Enhancing Unit Lifespan

Improving Efficiency

A well-maintained HVAC system operates at peak efficiency, reducing energy consumption and lowering utility bills. Clean filters, calibrated thermostats, and proper refrigerant levels ensure the system doesn’t overwork to achieve desired temperatures. Efficient operation minimizes strain on components, allowing the unit to perform optimally while conserving energy and maintaining comfort.

Enhancing Air Quality

Regular preventative maintenance is essential to keep your HVAC system running efficiently, extend its lifespan, and improve indoor air quality. While it might cost in the short term, getting maintenance done is the best way to get your system to run for years to come. Don’t wait for problems to arise—schedule a professional maintenance check today to protect your investment and enjoy peace of mind. See our AC maintenance page for more.